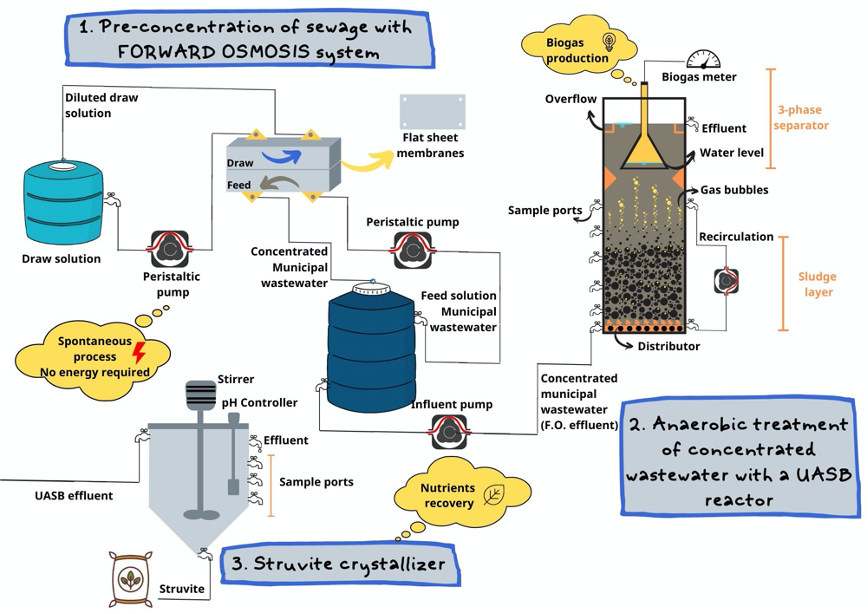

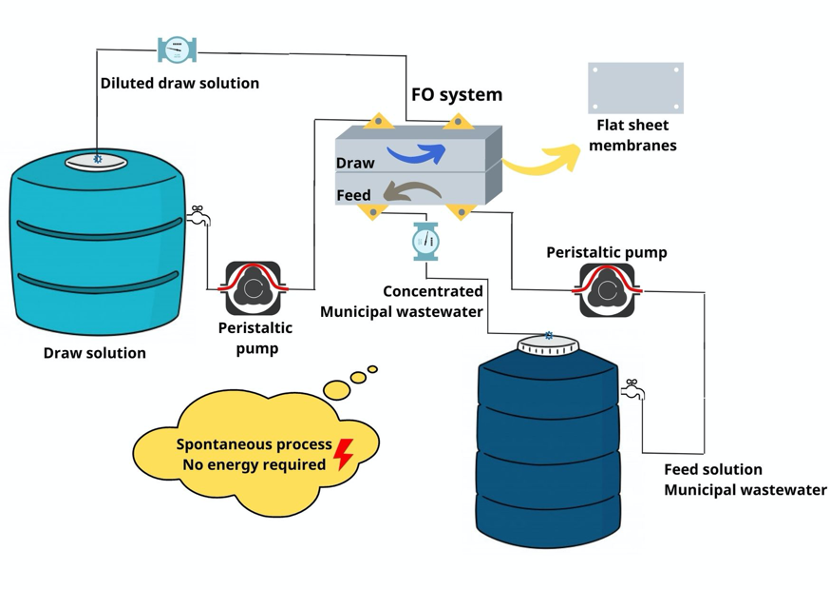

The FORWARD-WATER project consists of a forward osmosis (FO) system, an UASB reactor and a struvite crystallizer. FO is a membrane-based process that requires two solutions of different osmotic concentrations (high and low), separated by a semi- permeable membrane to be realized. The cornerstone of this process is the draw solution, which is an electrolytic solution characterized by high osmotic pressure, in order to generate a water flow from the low osmotic pressure fluid (i.e. sewage) into the high one (i.e. draw solution). The process takes place spontaneously, without the need to apply any external pressure due to the tendency of liquids to equalize the solute concentration. The condensation of municipal sewage achieved by this process enhances the anaerobic treatment by the UASB reactor and the chemical precipitation taking place in the struvite crystallizer for the recovery of energy and nutrients, respectively, thus maximizing the efficiency of the system. Subsequently sewage is treated anaerobically in the UASB reactor, where the organic matter of wastewater is converted into biogas, which can be used for energy production. Finally, in the struvite crystallizer nutrients are recovered by chemical precipitation.

FO process

In FORWARD-WATER a bench scale FO unit will be used in the Sanitary Engineering Laboratory (SEL) of the NTUA for the needs of this project, in order to concentrate the raw, municipal wastewater for further utilization of the contained energy and resources. Raw urban wastewater will be used by the WWTP of Psittalia (Athens, Greece) as the feed stream. The FO unit consists of the FO membrane cell having an effective membrane area (approximately 42 cm2) and two flow channels. Both the draw and feed solutions will continuously circulate in the main cell of the unit via 2 peristaltic pumps. The conductivity of both solutions will be constantly monitored so that the driving force of the process, the osmotic pressure, remains constant. At the same time, the weight reduction of the feed solution will be continuously recorded. Τhe FO process will be optimized regarding the draw solution and the membrane material.

UASB reactor

For the purpose of this project an existing UASB reactor with a working volume of 16 L will be applied; about 40% of its working volume will be filled with anaerobic sludge as inoculum (taken from an anaerobic digestion unit). The reactor will operate under continuous feed conditions at a temperature of 20 oC, while the condensed wastewater from the effluent of the FO unit will serve as feed stream.

The performance of the reactor will be monitored, while various operating parameters will be explored, in terms of biogas production optimization.

Struvite crystallizer

After the anaerobic treatment for energy recovery, chemical precipitation will be conducted in order to recover nutrients. Thus the effluent from the UASB reactor characterized by high nutrient concentrations will be led to a struvite crystallizer, where phosphorus will be precipitated as struvite by adding magnesium at a suitable concentration.